SurferJoe said:

Well - that was 20 minutes that I'll never get back.

What a waste.

Oh dear, I upset you..

Are you operating under the impression that I said you were wrong?

Is that why your upset?

If so, note that I never said you were wrong!

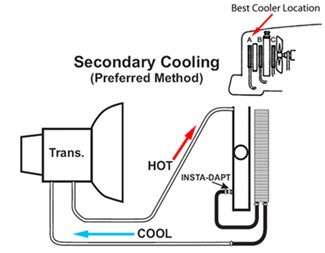

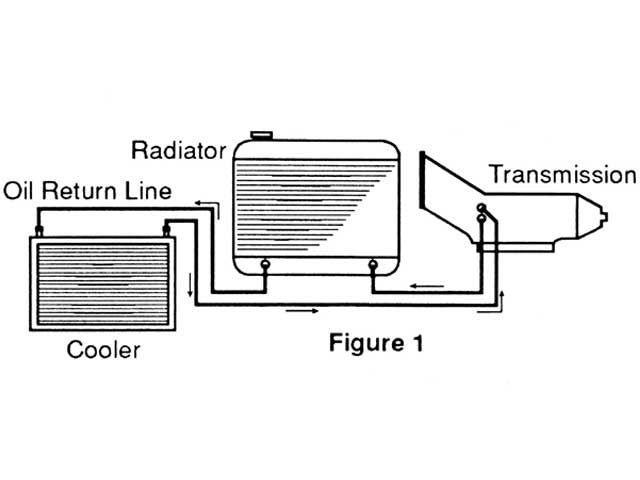

I simply pointed out your statement that a transmission air cooler (read heat exchanger) should go

before the transmission radiator cooler (read heat exchanger) and not

after is just your 'opinion' not to be confused with fact.

On that note..

It does not take much research time to realize there are basically 'two schools of thought' (read camps) with regards on how to install a transmission air cooler..

- Camp 1) Place it before the radiator cooler.[/*]

- Camp 2) Place it after the radiator cooler.[/*]

And which of the two camps you fall into tends to reflect the area you live in and/or the way you drive your vehicle..

For example

- Camp 1 types live in cold areas of the country, where the transmission fluid rarely if ever gets over high rating, so cold that the main concern is the fluid could in-fact get too cold.[/*]

- Camp 2 types live in warm to hot areas of the country, and/or drive their vehicles hard, as in tow trailers, where the transmission fluid can get up to and above the high rating, so hot that the main concern is the fluid getting too hot.[/*]

Still think your way is the only way and that I am just making all this stuff up about people other than me disagreeing with you?

Well know that there are many people in this world who recommend the air cooler be placed after the radiator cooler..

Many transmission, speed shops, trailer and towing companys recommend Case 2, you know people who's livelihood and reputations depend on what they say and do.

But don't take my word for it..

There is this new thing called google and you can use it to verify what I am claiming..

But based on your snarky closed minding reply(s) thus far..

I think it is safe to assume that you don't know how to use google search, so allow me to post some pictures below that prove what I am saying is true and debunk your 'idea' that your way is the only way to do it.

Enjoy

See.. not such arcane reasoning as you would have us believe..

And that is just a few pics out there..

Many major manufactures of transmission air coolers instructions show the air cooler to be installed after the rad cooler not before as you recommended.

Note I say many manufactures.. but could actually say most if not all in that I have yet to find one that even shows it being installed before the rad cooler let alone offering that as an option.

So, based on that, one could argue my reasoning, ie case 2 is as popular if not more so than your case 1..

Will even go as far as to say your method is the one that is in the minority and requires arcane reasoning..

In

SUMMARY

Of the two, heat is the bigger problem..

As most ATF temp range charts will confirm, cooler is better! i.e.

Sadly, based on the range shown in such charts, many get the 'false' impression that temperatures below 175F are 'bad'!

Clearly you are one who falls into this category..

But in fact, ATF cooler than 175 is not a bad thing at all!!

As a mater of fact, based on the AMSOIL chart regular petroleum ATF is good to go between ~10F to ~175F, i.e.

So, knowing in advance the rad and air cooler combo can not cool the ATF to ambient (read outside) temperature, that means it would have to be alot colder than 10F to cause the ATF fluid to be cooled down to 10F.. In English, think North Dakota cold before you would have to worry about getting the ATF too cold.. Where as on the other hand, it does not even have to be a Arizona 110F day to over heat a tranny.. You can do that even on a cool 90F day going up hill with a loaded trooper, or towing something.

Hope that helps!